I’d like to say that we are on schedule and that everything has gone according to plan! But that is not the reality of drilling in Antarctica when you’re developing an entirely new approach. We’ve had steady downward progress, that much is good, and we’ve passed several key milestones and set new depth records for rotary ice drilling. But it’s come by way of hard work to overcome daily challenges, with a lot of emotional ups and downs.

Through many fits and starts, we managed to start cutting continuous new borehole in ice at depths well below the packer unit that creates a seal we need to circulate drilling fluid. By the end of one particularly good day we had reached 259 m (850 ft). Terrific, a new record! Soon after that we reached 390 m (1,281 ft). Eventually, after a series of good runs, we ended up at 624 m (2,050 ft) – well beyond the expected depth of ice at Minna Bluff!

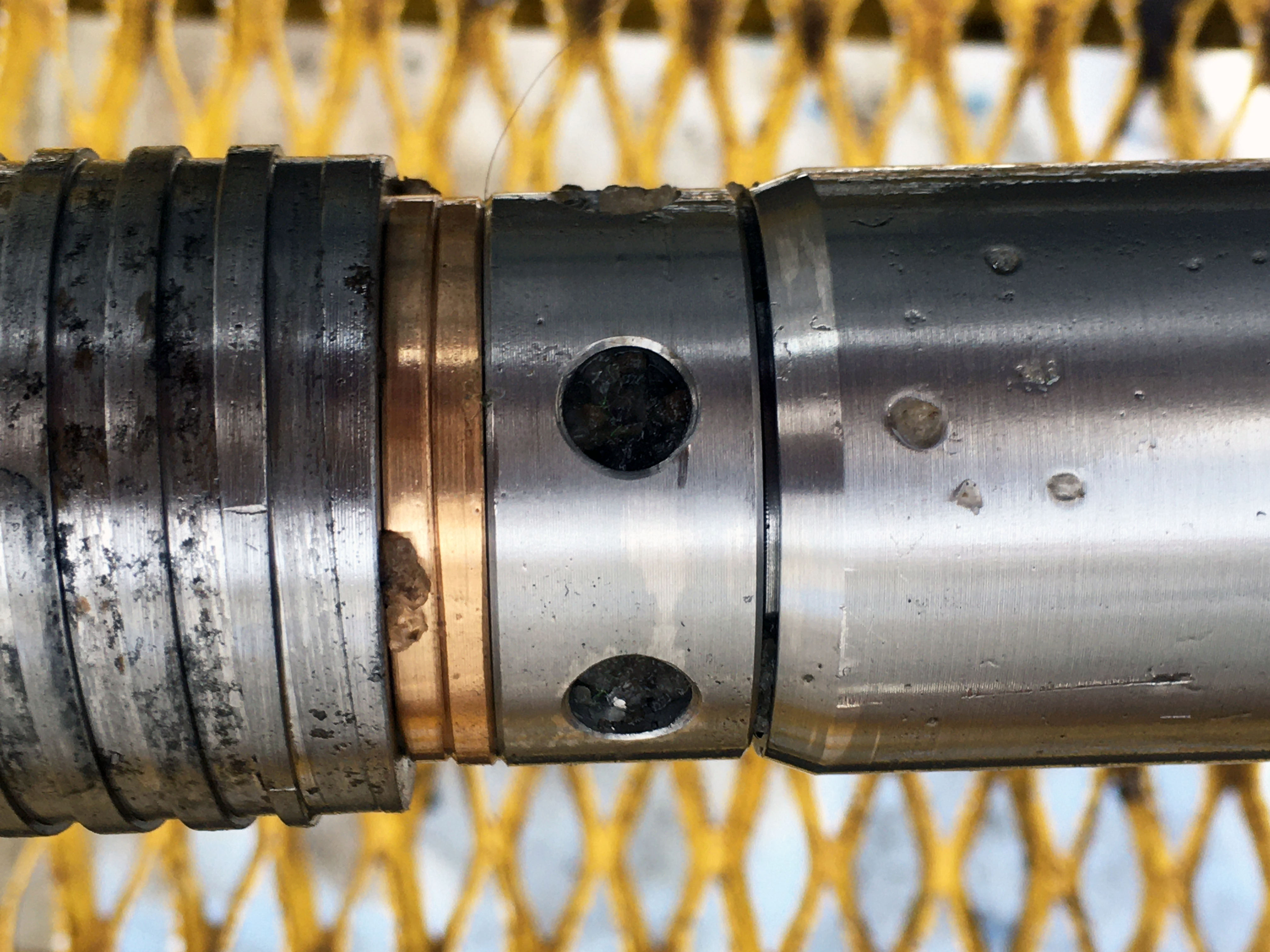

A few days ago we thought we had finally hit bottom of the glacial ice. A radar profile across this area shows the ice thickness to be about 600 meters (or 1,970 feet). We were now past that depth by a fair way — about 2,220 ft – when the ice-cutting bit torqued up, the drill showed increased weight on bit, and there were new vibrations passing through the drill itself. To the drillers, it felt like bedrock! So we pulled up the center part of the ice bit, which can be detached with a special tool spooled down on a wire line, and we saw that its cutting surfaces were marred by scratches and nicks suggestive of abrading rock. Exciting!!

The next step was to set up for rock coring. Our system uses a detachable cutting assembly with a diamond impregnated bit for cutting rock, attached by a complicated mechanism that eventually feeds rock into cylindrical core barrels behind. It’s all machined out of stainless steel and is something to behold for its beauty and heft.

The only problem in our case is that the coring assembly has to be lowered through a column of drilling fluid carrying suspended ice chips, and they tend to collect and pack off in the face of the descending tool. Once latched in place, we tried time and again to get fluid to pass through so we could drill with the circulation we need to cool the bit and remove cuttings. No luck. Each time we pulled up the coring assembly, we found a pack of ice chips in the ‘waterways’.

But our drilling team never gives up. After making modifications to enlarge the openings of the fluid pathways by careful work on the drill press, it finally worked as intended. Only this time, what we pulled up was not rock! Ice core! This was a major disappointment because we thought certainly we were at the bedrock interface. Instead, more ice. Our excitement days earlier of finally getting to bedrock was premature.

So now we are picking ourselves up and planning the next steps to take. Often it seems like its really the end, and yet so far we have been able to reassess, think about the problem, modify the tooling, and try again. It’s worked to this point, but will our luck finally play out?

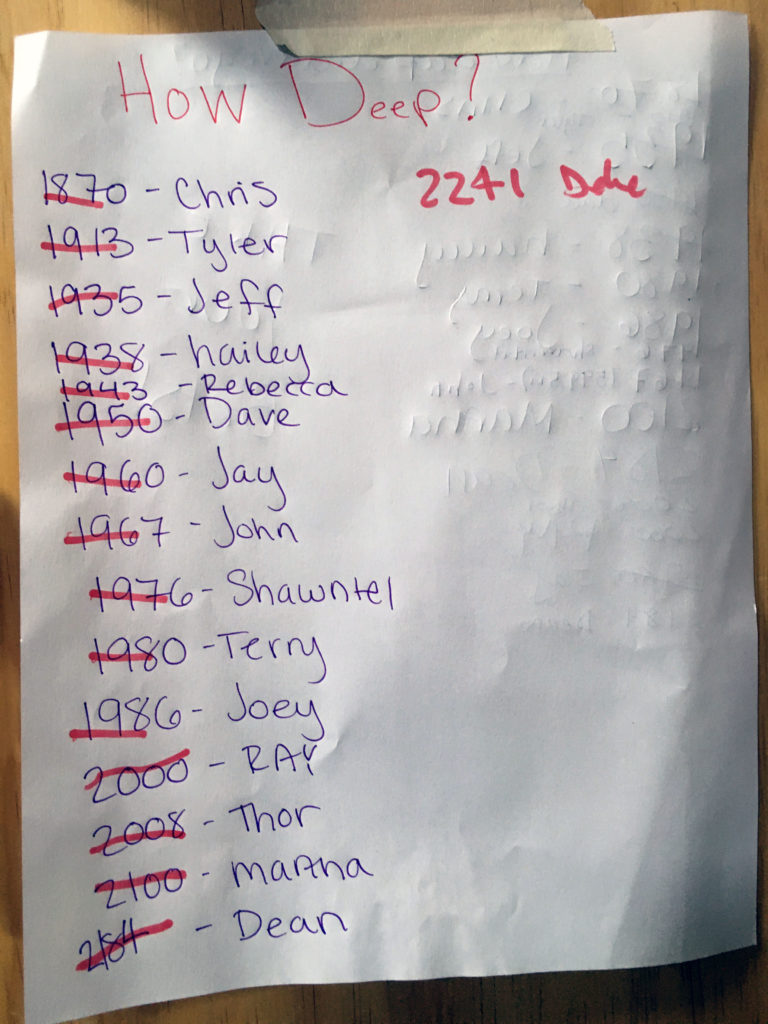

Everyone in camp has been pulling for us and they’ve gotten involved in many ways. To celebrate making it to deep ice, Hailey and Martha made a ‘stratigraphic’ cake that could be sliced through layers of firn, ice and rock. After passing the conceptually important midway point at 1,000 feet, we started a galley pool to place bets on how deep we’d have to go to reach bedrock. One by one, we blew by the wagers to over 2,200 feet.

This is the first season in Antarctica that we’ve been able to really test the deep ice-cutting and rock-coring capabilities. In previous seasons we explored the vagaries of getting deep into firn and we learned how easily glacial ice can be fractured by simple fluid overpressure. As before, we’ve learned a tremendous amount this season too. And we’ve been able to reach several key milestones. First of these is simply to have penetrated into deep ice below the firn with rotary drilling using fluid circulation to evacuate cuttings. Once safely through the packer, the drill cuts ice relatively easily.

Another big accomplishment has been successful use of pressure relief valves and overflow reservoirs to prevent circulating fluid from spiking in pressure and threatening to fracture the ice. With an adjustable valve that activates at a set pressure, we are able to drill and keep fluid pressures in a tolerable range. The pressure relief valve has proved itself many times so far.

A major achievement so far is to drill very deep in ice and get close to the glacial bed. Making it through 2,000 ft of ice so quickly is kind of mind-boggling to me still. To see dirty ice cuttings coming across the fluid return, to catch a thick layer of silty mud in a filter bag, and to see scratches on the ice-cutting bit are all good signs that we’ve made a long-term dream a tangible reality. We’re still hoping to get some actual rock core, but we are really close!

In a large sense, a lot of the RAID drilling process consists of fluid management. We run a recirculation loop that goes down the borehole, across the cutting bit, back up the drill pipe, into a module that separates ice cuttings from fluid, and then back down the hole. As described in earlier posts, the system is simple in concept but there are innumerable places for fluid to get hung up. Ideally, we use automation to monitor status of all the pumps and tanks, enabling us to keep up a steady flow of about 20 gal/min. Of course, the deeper we go, we have to keep adding fluid, so then the game becomes one of monitoring levels and keeping the fluid free of ice.

Another key process is keeping fluid and tools cold. Here at Minna Bluff the days can get warm, even above freezing. Any thawing can introduce liquid water into our system, which can then clog up the cold plumbing as ice. Ironically, we need an air conditioning unit here in order to cool down the drilling fluid before we pump it down the borehole. Any fluid on the surface can absorb thermal energy from the sun and if we put warm fluid (meaning just above freezing) down the hole, then ice and borehole cuttings can melt and refreeze in our hoses and lines, causing all kinds of headaches. It’s mainly a problem for us here near the coast where summer air temperatures are warm. When we are on the high polar ice cap, it will be much colder (like -40 °C) so the fluid will always stay cold on it’s own. For now, it’s a time-consuming process of fluid management through the maze of hoses and pipes.

Often, ice gets into the fluid separation unit, melts, and refreezes, causing blockages in valves, pumps, and hoses. Sometimes it’s possible to blow out the blockages with compressed air, or suck them out with pumps. But once a section is frozen up in a room kept to about -20 °C (-5 °F) the last resort is to thaw out the blocked section, re-establish flow, and hope that it doesn’t refreeze again or just transfer the problem to another section! As a result, we go through a lot of propane bottles for spot torching.

Despite the challenges it keeps giving, this hole has been good to us. Now we know that we can go deep and the lessons learned will help the next hole to be at least as rapid and successful as the last.

Photos by John Goodge.

The views expressed here are personal reflections that do not represent either the RAID project or the National Science Foundation.